Trade Turner

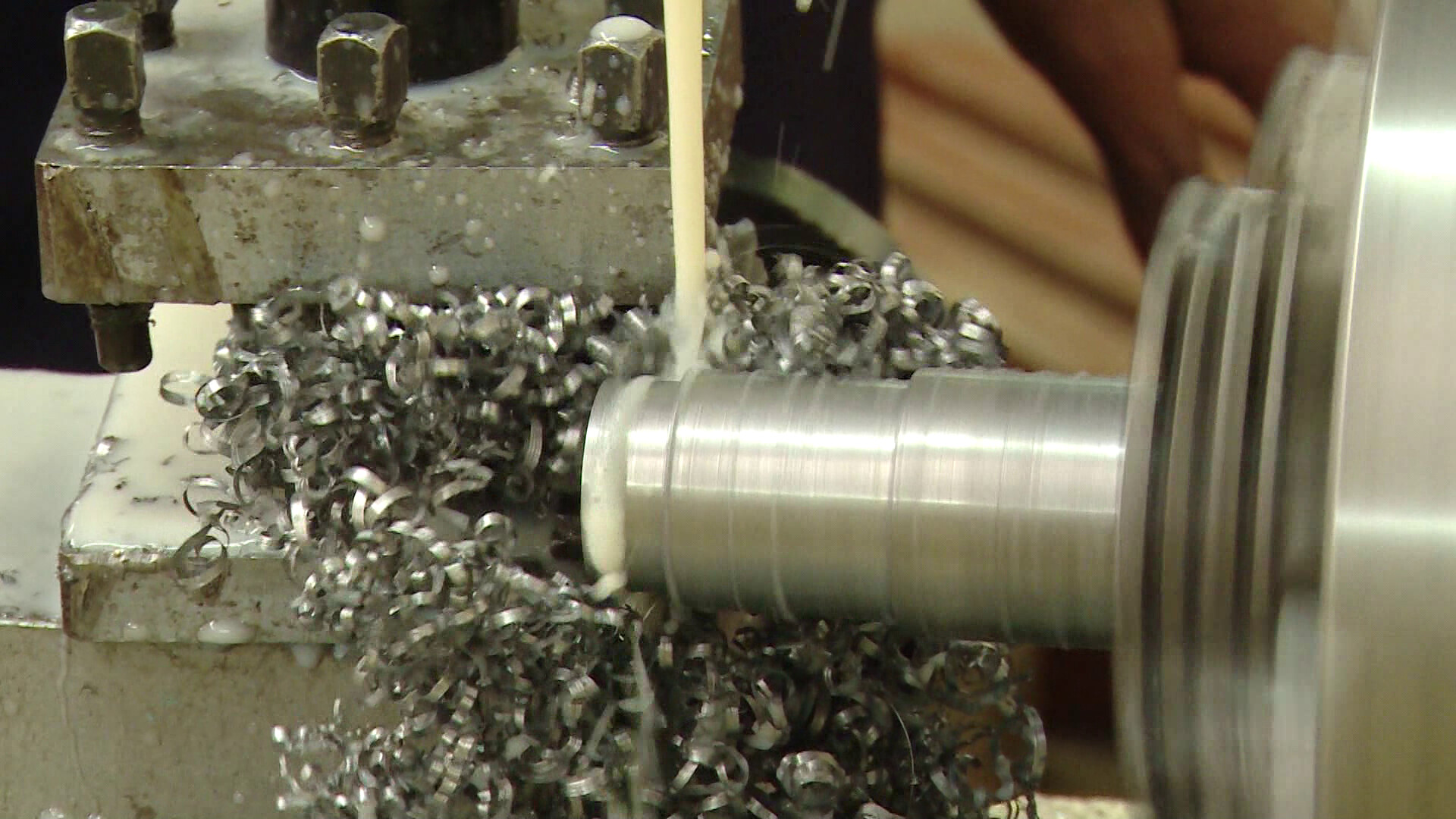

Knowledge in different types of tool grinding, parallel, taper and stepped turning, boring, thread cutting and fitting; simple capston and turret lathe operations, CNC trainer lathe operations with simple programmes are imparted in this trade.

TURNER – LEARNING OUTCOMES – ITI

FIRST YEAR:

FIRST YEAR:

- Plan and organize the work to make job as per specification applying different types of basic fitting operations & check for dimensional accuracy following safety precautions. [Basic Fitting Operation – Marking, Hack sawing, filing, drilling, taping ]

- Set different shaped jobs on different chuck and demonstrate conventional lathe machine operation observing standard operation practice. [Different chucks: – 3 jaws & 4 jaws, different shaped jobs: – round, hexagonal, square]

- Prepare different cutting tool to produce jobs to appropriate accuracy by performing different turning operations. [Different cutting tool – V tool, side cutting, parting, thread cutting (both LH & RH), Appropriate accuracy: – ±0.06mm, Different turning operation – Plain, facing, drilling, boring (counter & stepped), grooving, Parallel Turning, Step Turning, parting, chamfering, U -cut, Reaming, internal recess,

- Test the alignment of lathe by checking different parameters and adjust the tool post. [Different parameters – Axial slip of main spindle, true running of head stock, parallelism of main spindle, alignment of both the ]

- Set different components of machine & parameters to produce taper/ angular components and ensure proper assembly of the components. [Different component of machine: – Form tool, Compound slide, tail stock offset, taper turning attachment. Different machine parameters- Feed, speed, depth of ]

- Set the different machining parameter & tools to prepare job by performing different boring operations. [Different machine parameter- Feed, speed & depth of cut; Different boring operation – Plain, stepped & eccentric]

- Set the different machining parameters to produce different threaded components applying method/ technique and test for proper assembly of the components. [Different thread: – BSW, Metric, Square, ACME, ]

- Set the different machining parameter & lathe accessories to produce components applying techniques and rules and check the accuracy. [Different machining parameters: – Speed, feed & depth of cut; Different lathe accessories: – Driving Plate, Steady rest, dog carrier and different ]

- Plan and perform basic maintenance of lathe & grinding machine and examine their functionality.

SECOND YEAR:

- Plan & set the machine parameter to produce precision engineering component to appropriate accuracy by performing different turning operation. [Appropriate accuracy –±0.02mm/ (MT – 3) (proof turning); Different turning operation – Plain turning, taper turning, boring threading, knurling, grooving, chamfering etc.]

- Set & Produce components on irregular shaped job using different lathe [Different Lathe accessories: – Face plate, angle plate]

- Plan and set the machine using lathe attachment to produce different utility component/ item as per drawing. [Different utility component/ item – Crank shaft (single throw), stub arbour with accessories ]

- Set the machining parameters and produce & assemble components by performing different boring operations with an appropriate accuracy. [Different boring operation – eccentric boring, stepped boring; appropriate accuracy – ±0.05mm]

- Calculate to set machine setting to produce different complex threaded component and check for functionality. [Different complex threaded component- Half nut, multi start threads (BSW, Metric & Square)]

- Set (both job and tool) CNC turn centre and produce components as per drawing by preparing part

- Manufacture and assemble components to produce utility items by performing different operations & observing principle of interchangeability and check functionality. [Utility item:- screw jack/ vice spindle/ Box nut, marking block, drill chuck, collet chuck etc.; different operations: – threading (Square, BSW, ACME, Metric), Thread on taper, different boring (Plain, stepped)]

- Make a process plan to produce components by performing special operations on lathe and check for accuracy. [Accuracy – ±0.02mm or proof machining & ±0.05mm bore; Special operation – Worm shaft cutting (shaft) boring, threading ]

TURNER CAREER PROGRESSION PATHWAYS – ITI

- Can join industry as Technician and will progress further as Senior Technician, Supervisor and can rise to the level of Manager.

- Can become Entrepreneur in the related field.

- Can appear in 10+2 examination through National Institute of Open Schooling (NIOS) for acquiring higher secondary certificate and can go further for General/ Technical education.

- Can take admission in diploma course in notified branches of Engineering by lateral entry.

- Can join Apprenticeship programme in different types of industries leading to National Apprenticeship certificate (NAC).

- Can join Crafts Instructor Training Scheme (CITS) in the trade for becoming instructor in ITIs.

- Can join Advanced Diploma (Vocational) courses under DGT as applicable.

TURNER JOB ROLE – ITI

TURNER JOB ROLE – ITI

- Lathe Operator makes metal articles to required specifications using lathe and cutting tools. Studies drawings and other specifications of parts to be made. Selects metal, holds it in chuck, fixture on lathe as required, centres it by manipulating chuck jaws or otherwise using dial indicator or marking block and securely tightens it in position. Selects correct cutting tool, grinds it if necessary and holds it tight in tool post at correct height. Sets feed and speed and starts machine. Manipulates hand wheels or starts automatic controls to guide cutting tool into or along metal. Controls flow of coolant (cutting lubricant) on edge of tool. Arranges gears in machine to obtain required pitch for screw cutting. Calculates tapers and sets machine for taper turning, controls lathe during operation by means of hand wheels and levers and frequently checks progress of cutting with measuring instruments such as calipers and rule, micrometers, etc. Stops machine, removes completed part and checks it further with instruments to ensure accuracy. Repeats operations if necessary. Cleans and oils machine. Demonstrate the setting &operation of CNC turning machine and produce components as per drawing by preparing part programmes. May be designated as Turner according to nature of work done. May improvise devices and make simple adjustments to machine. May recondition lathe tools.

- Plan and organize assigned work and detect & resolve issues during execution. Demonstrate possible solutions and agree tasks within the team. Communicate with required clarity and understand technical English. Sensitive to environment, self-learning and productivity.

Turner Entry Qualification & Course Durations – ITI

• Passed 10th class examination with Science and Mathematics or its equivalent.

• 2years.

Ramakrishna Mission Vidyalaya Private Industrial Training Institute, was founded in the year 1951 with the intention of eradicating un-employment among youth, and providing skilled man power to Industries in and around Coimbatore. In a humble way, we started with two trades namely Fitter and Turner with the affiliation and financial support from the Government of Tamilnadu. In the year 1982, a two year course on Draughtsman Mechanical, and Mechanic (Motor Vehicle) was started with the affiliation from National Council for Vocational Training ( NCVT), Government of India. In the same year two year Fitter course got affiliated with NCVT. In the year 1992, a two year course in wireman was started with affiliation from NCVT. In the same year Two year Turner course got affiliated with NCVT. Presently our students’ strength is 200.

Ramakrishna Mission Vidyalaya Private Industrial Training Institute, was founded in the year 1951 with the intention of eradicating un-employment among youth, and providing skilled man power to Industries in and around Coimbatore. In a humble way, we started with two trades namely Fitter and Turner with the affiliation and financial support from the Government of Tamilnadu. In the year 1982, a two year course on Draughtsman Mechanical, and Mechanic (Motor Vehicle) was started with the affiliation from National Council for Vocational Training ( NCVT), Government of India. In the same year two year Fitter course got affiliated with NCVT. In the year 1992, a two year course in wireman was started with affiliation from NCVT. In the same year Two year Turner course got affiliated with NCVT. Presently our students’ strength is 200.