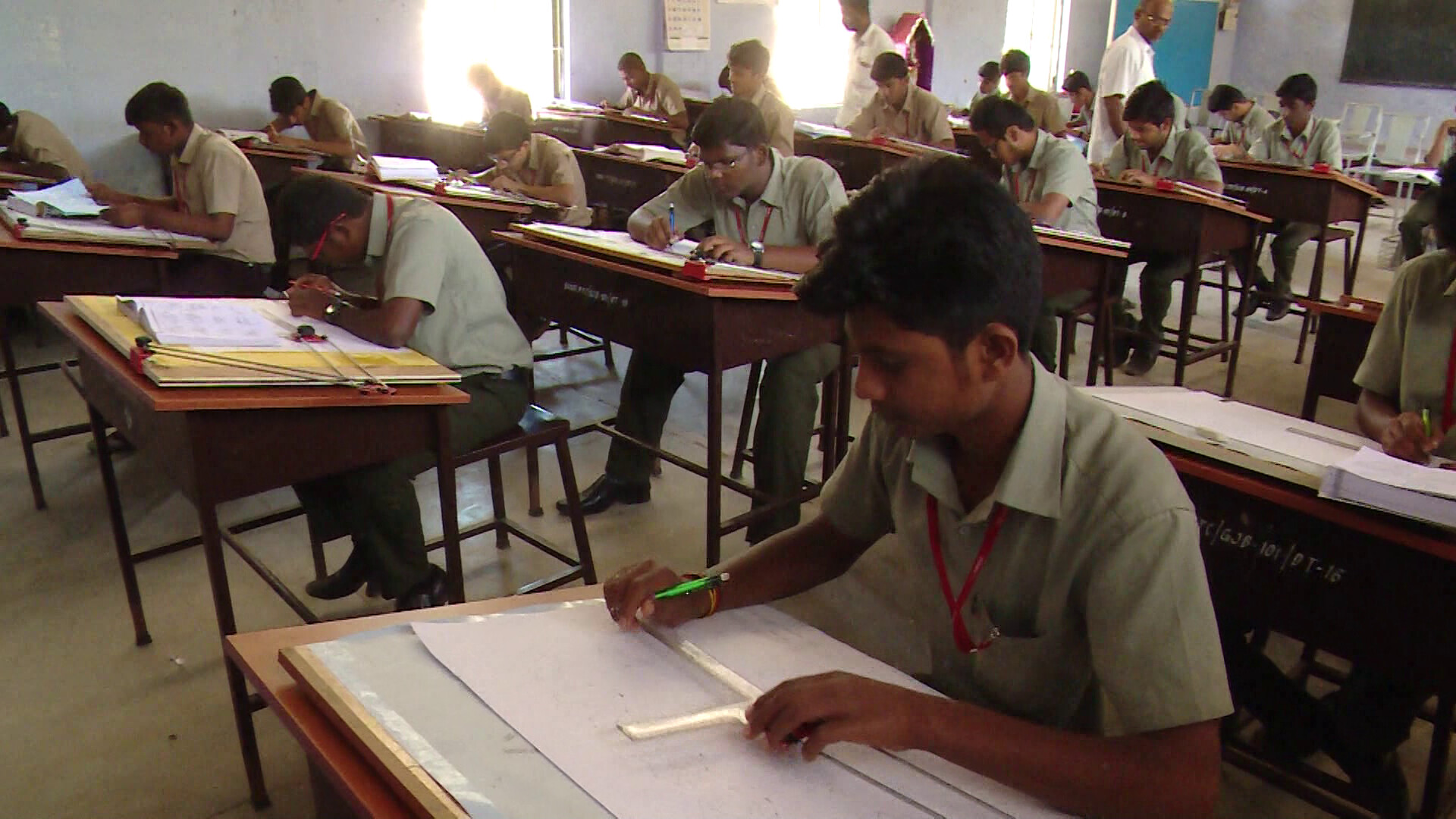

Trade Draughtsman Mechanical

Knowledge in free hand sketch of machine parts in the shop floor, projection of machine components, interpenetration, developing simple objects, fasteners, details & assembly drawings of machine parts, piping drawings, welding symbols, working drawing of gears, cams, jigs & fixtures, tracing and printing. Working knowledge in AutoCAD and pro-E software are imparted in this trade.

DRAUGHTSMAN MECHANICAL – LEARNING OUTCOMES

FIRST YEAR:

FIRST YEAR:

1. Construct different Geometrical figures using drawing Instruments following safety precautions.

2. Draw orthographic Projections giving proper dimensioning with title block and heading using appropriate line type and scale.

3. Construct free hand sketches of simple machine parts with correct proportions.

4. Construct plain scale, comparative scale, diagonal scale and vernier scale.

5. Draw Sectional views showing orthographic projections.

6. Develop surface and interpenetration of solid in orthographic projection.

7. Draw isometric projection from orthographic views (and vice-versa) and draw oblique projection from orthographic views.

8. Draw and indicate the specification of different types of fasteners, welds and locking devices as per SP-46:2003

9. Acquire basic knowledge on tools and equipment of Allied trades viz. Fitter, Turner, Machinist, Sheet Metal Worker, Welder, Foundry man, Electrician and Maintenance Motor Vehicles.

10. Construct different types of gears, couplings and bearings with tolerance dimension and indicating surface finish symbol.

11. Perform computer application and Create 2D objects on CAD drawing space using commands from ribbon, menu bar, toolbars and by typing in command prompt.

SECOND YEAR:

12. Construct projection views of geometrical figures with dimension and annotation on CAD in model space and viewport in layout space.

13. Draw in CAD detail and assembly drawing of machine parts viz., Pulleys, Pipe fittings, Gears and Cams applying range of cognitive and practical skills.

14. Construct drawing of engine parts with detailed and assembly in template layout applying quality concept in CAD.

15. Create 3D solid by switching to 3D modeling workspace in CAD, generate views, Print Preview and Plotting.

16.Construct detailed and assembled drawing applying conventional sign & symbols using CAD.

17. Prepare drawing of machine part by measuring with gauges and measuring instruments.

18. Draw a machine shop layout considering process path and ergonomics (human factor).

19. Create and plot assembly and detail views of machine part with Dimensions,Annotations, Title Block and Bill of materials in Solid Works/AutoCAD Inventor/ 3D Modeling.

20. Create production drawing of machine part.

DRAUGHTSMAN MECHANICAL CAREER PROGRESSION PATHWAYS – ITI

- Can join industry as Technician and will progress further as Senior Technician, Supervisor and can rise up to the level of Manager.

- Can become Entrepreneur in the related field.

- Can appear in 10+2 examination through National Institute of Open Schooling (NIOS) for acquiring higher secondary certificate and can go further for General/ Technical education.

- Can take admission in diploma course in notified branches of Engineering by lateral entry.

- Can join Apprenticeship programme in different types of industries leading to National Apprenticeship certificate (NAC).

- Can join Crafts Instructor Training Scheme (CITS) in the trade for becoming instructor in ITIs.

- Can join Advanced diploma (Vocational) courses conducted by DG

DRAUGHTSMAN MECHANICAL JOB ROLE – ITI

DRAUGHTSMAN MECHANICAL JOB ROLE – ITI

Draughtsman Mechanical; prepares drawings of machines, plants, mechanical components, equipments etc. from sketches, notes, data or sample for purposes of manufacture or repairs. Takes instructions from Mechanical Engineer and calculates dimensions as required, from available materials (notes, data etc.) or sample. Draws to scale detailed drawings, assembly drawings,showing plan, elevations, sectional views etc.according to nature of work and operations required. Prints (writes) dimensions, tolerances, material to be used and other details to give clear picture and facilitate understanding. Maintains copies of drawings and makes prints. They may trace drawings and may design simple mechanical parts. May prepare estimates for materials and labour required. May specialize in making drawings of jigs and tools and be designated accordingly. Create component parts on Drawing Space using toolbars,commands and menus in CAD application software and also creating objects on 3D modeling space in CAD viewing printable drawing and plotting them.

Draughtsman Mechanical selects the appropriate equipment and drawing software to use based on the type and complexity of the drawing functions to be carried out and the use of a CAD system linked bills of material, file management and associated customization of installed software including the use of macros, menus and default settings.

In addition, Draughtsman Mechanical has the ability to visualize the job, good coordination, mechanical attitude, manual dexterity and perform work related mathematical calculations.

DRAUGHTSMAN MECHANICAL JOB SCOPE – ITI

- DESIGN DEPARTMENT.

- AUTOCAD DRAUGHTSMAN.

- DRAUGHTSMAN PIPING.

- DRAUGHTSMAN STRUCTURAL.

- PATTERN MAKING DEPARTMENT.

- SHEET METAL WORK.

- FOUNDRY DRAUGHTSMAN.

DRAUGHTSMAN MECHANICAL Entry Qualification & Course Durations – ITI

• Passed 10th class examination with Science and Mathematics or its equivalent.

• 2 years.

Ramakrishna Mission Vidyalaya Private Industrial Training Institute, was founded in the year 1951 with the intention of eradicating un-employment among youth, and providing skilled man power to Industries in and around Coimbatore. In a humble way, we started with two trades namely Fitter and Turner with the affiliation and financial support from the Government of Tamilnadu. In the year 1982, a two year course on Draughtsman Mechanical, and Mechanic (Motor Vehicle) was started with the affiliation from National Council for Vocational Training ( NCVT), Government of India. In the same year two year Fitter course got affiliated with NCVT. In the year 1992, a two year course in wireman was started with affiliation from NCVT. In the same year Two year Turner course got affiliated with NCVT. Presently our students’ strength is 200.

Ramakrishna Mission Vidyalaya Private Industrial Training Institute, was founded in the year 1951 with the intention of eradicating un-employment among youth, and providing skilled man power to Industries in and around Coimbatore. In a humble way, we started with two trades namely Fitter and Turner with the affiliation and financial support from the Government of Tamilnadu. In the year 1982, a two year course on Draughtsman Mechanical, and Mechanic (Motor Vehicle) was started with the affiliation from National Council for Vocational Training ( NCVT), Government of India. In the same year two year Fitter course got affiliated with NCVT. In the year 1992, a two year course in wireman was started with affiliation from NCVT. In the same year Two year Turner course got affiliated with NCVT. Presently our students’ strength is 200.